Cold-Pressed Avocado Oil Extraction Technology

SIMEC focus on the technology and equipment to produce guacamole and cold-pressed avocado oil.

The avocado fruit is widely regarded as an important fruit for its nutritional values, as it is rich in vital nutrients for the human body. There has recently been an increasing demand in antioxidants, given their beneficial effects on human health. In this respect, avocados contain three of the most important ones, which are vitamins. Avocado fat consists predominantly of mono-unsaturated oleic acid, which has been found to reduce harmful low-density lipoprotein cholesterol, while maintaining beneficial high-density lipoprotein cholesterol, and to perform better than typical low-fat diets.

Although avocado is primarily consumed fresh, a substantial increase in the use of avocado-based products (e.g., guacamole) and oil for cosmetics and culinary purposes also suggest further market growth. In general, an avocado fruit is roughly pear-shaped and more or less elongated. Its weight may range from 60 g to 700 g. The relative amount of pulp varies from 60 to 75% according to the cultivar. The oil content may also vary widely. The main quantity of oil is in the pulp/flesh of the avocado fruit.

|  |

Hass avocado has large amount of flesh with a high oil content. Depending on the location of the orchard, the oil content of Hass variety fruit flesh can range from 16-17% in September to 25-30% in April depending on the fruit ripening stage. The kernel/stone contains only about 1% of oil, whereas the skin accounts for less than 4%.

The characteristics of avocado fruits can change depending on multiple variables. Variety, ripeness stage, geographical area, fruit humidity are some of main factors that affect extraction rates and the final quality of avocado oil.

As a leading technology developer, SIMEC leverages its significant experience and technological expertise to develop a novel extraction method to obtain high-quality avocado edible oil, so called cold-pressed extra-virgin avocado oil (CPAO in short) which is not refined and maintains the chemical, organoleptic and flavour profile of the fruit flesh.

|  |  |

For small scale avocado oil production, avocado oil extraction is generally obtained by peeling and destoning the fruit, mashing the pulp, then malaxing the paste, and pressing the oil. The corresponding equipment required include avocado peeling and destoning machine, pulping machine, malaxer, hydraulic avocado oil press, oil purification apparatus. SIMEC offer all the equipment and complete technology.

For large scale processing plant, centrifuge separation technology is recommended to extract avocado oil in a continuous and efficient mode.

Step One: Fruit washing, destoning, peeling and mash preparation

Avocado fruit washing is performed by immersion and jet showering in order to remove dust from the surface of the fruits. Then a multi-channel avocado pasting machine will separate nut and peel from the pulp, then make the pulp into mash form. The nuts are 100% separated.

Skin separation needs to be calibrated according to the desidered quality, since the proportion of skin into the processed mash may affect the pigment composition of avocado oil. Pigments are important for the intensity of the green colour, its stability and its healthy effects.

Step Two: Avocado mash conditioning and malaxing

The avocado pulp mash with a variable proportion of peel is pumped into a colloid mill for further conditioning. Avocado oil comes in a finely dispersed emulsion inside the cells of the fruit pulp, so the extraction process requires rupturing not only the cell walls, but also the structure of the emulsion.

Colloid mill has the important effect of chopping cutting very finely the peel for maximum pigment extraction, and cuts the filaments remained in the paste and, at the same time, to minimize the emulsion. The avocado paste can be circulated through return pipes and re-grinded easily to achieve the desired emulsion fineness. Qualified pulp mash is temporarily stored and conditioned in the agitating tank.

The conditioning process provides the possibility to heat the mash before malaxing with the positive effect of increasing volatile compounds and reducing malaxing time up to 50%.

|  |

After conditioning, the avocado mash is pumped into malaxing section equipped with multi sets of malaxers (kneading machines). Each malaxing machine consists of a stainless steel tank with a central screw ribbon stirring the mash slowly and continuously at a monitored temperature.

Small oil drops are released during fruit milling, then during malaxing merge into large drops (coalescence phenomena) that can be easily separated by centrifugal extraction.

On average we should consider as optimal a malaxer temperature lower than 50°C and a malaxing time between 30 and 45 min. 10%-20% of hot water is added during malaxing/kneading process. The addition of water processing aids (e.g., enzymes and talcum powder) is acceptable, but no chemical solvents can be used.

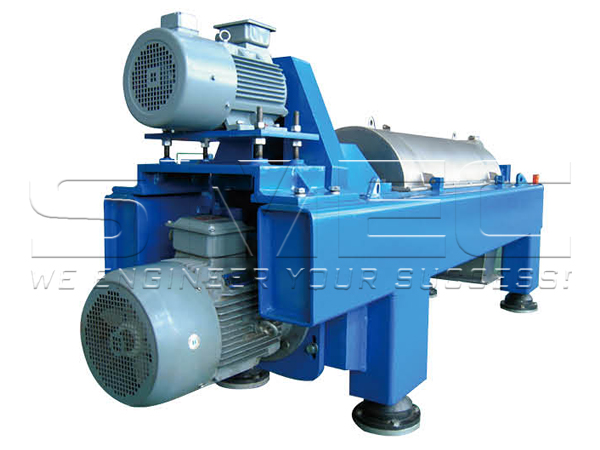

Step Three: Oil extraction

The separation of oil from solid and liquid phases is done using a decanter centrifuge that exploits the centripetal acceleration to separate continuously a mixture of particulate solids and liquids with phases having different densities. The avocado pulp mash is separated into oil, vegetation water and solids (exhausted pulp and residual skin).

The oil phase and the water phase are collected separately under the decanter centrifuge. The oil phase is pumped out to a vertical purifier centrifuge, while the water phase is pumped out to a vertical concentrator centrifuge.

|  |

Step Four: Oil purification and recovery

The avocado oil flowing from the decanter centrifuge still has a certain amount of water and solids. Vegetation water from the decanter should still contain a small quantity of residual oil. Both liquid phases are sent to vertical centrifuges. A disk stack centrifuge is for final oil purification to remove residual water and solids. A second disk stack centrifuge is used to recover residual oil from the vegetation water flowing from the decanter.

Extra virgin avocado oil extraction should be carried out using only mechanical methods including hydraulic oil press, and decanter centrifuge at low temperatures (<50°C). The cold-pressed extraction method can yield an oil with significantly higher pigment levels, a stronger flavour and, consequentely higher health benefits.

The chemical composition and organoleptic profile of cold-pressed extra virgin avocado oil are reported in the table below.

| Parameter | Description/value |

|---|---|

| Odour and taste | The characteristic avocado flavour and sensory assessment shows at least moderate (above 40 on a 100-point scale) levels of grassy and mushroomy/buttery hints with some smoky notes. The Hass cultivar gives an avocado oil with grassy and buttery/mushroom-like flavours. Fuerte cultivar that has a more mushroomy flavour and fewer typical avocado flavours. |

| Colour | Nice and intense green |

| Stability | 2 years at room temperature when stored under nitrogen and in the dark |

| Acid value | <1% |

| Peroxide value (meq/kg oil) | <4 |

| Free fatty acid (% as oleic acid) | <0.5% |

| Smoke point | >250°C |

| Moisture | <0.1% |

| Palmitic acid (16:0) | 10%-25% |

| Palmitoleic acid (16:1) | 2%-8% |

| Stearic acid (18:0) | 0.1%-0.4% |

| Oleic acid (18:1) | 60%-80% |

| Linoleic acid (18:2) | 7%-20% |

| Linolenic acid (18:3) | 0.2%-1% |

| Vitamin E | 70 mg/kg – 190 mg/kg |